Making Best Use Of Efficiency: Choosing the Right Aftermarket Construction Parts for Your Fleet

Making Best Use Of Efficiency: Choosing the Right Aftermarket Construction Parts for Your Fleet

Blog Article

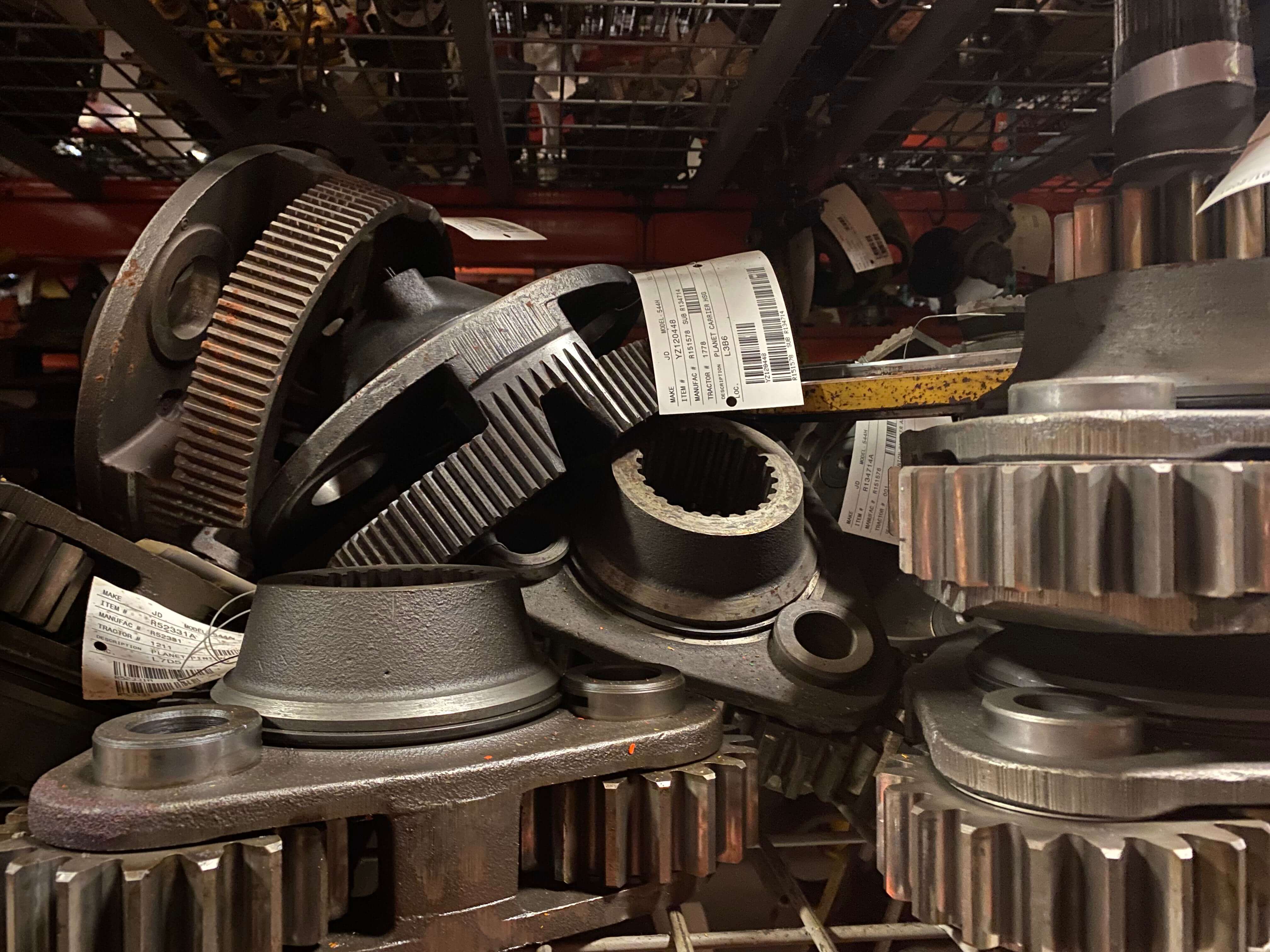

Unlocking the Cost-Saving Benefits of Aftermarket Components for Heavy Machinery

When it comes to heavy equipment maintenance, the selection between initial tools maker (OEM) parts and aftermarket components is a decision that holds relevance beyond the surface. The marketplace for aftermarket parts has actually been steadily growing as a result of different variables that make them an appealing choice for cost-conscious organizations wanting to enhance their upkeep spending plans. By exploring the cost-saving advantages of aftermarket parts, one can discover a world of potential benefits that not only effect the economic base line but additionally the functional efficiency of heavy machinery.

Quality Efficiency at Lower Expenses

The premium top quality performance provided by aftermarket parts for heavy machinery comes at substantially reduced prices contrasted to OEM components. Aftermarket components makers have actually had the ability to link the void in between top quality and price, providing an economical remedy for organizations aiming to keep and fix their hefty equipment without endangering on performance. These components undergo rigorous testing processes to guarantee they fulfill market requirements and specifications, offering a degree of integrity that is on the same level with OEM components.

One trick advantage of aftermarket components is their affordable prices, which can lead to substantial cost financial savings for organizations over time. By deciding for aftermarket parts, business can access top notch elements at a fraction of the cost of OEM components, permitting them to designate their sources a lot more effectively and successfully. The accessibility of aftermarket components from a broad array of vendors increases competitors in the market, driving costs down and offering customers extra options to pick from when sourcing components for their hefty equipment. In general, the mix of quality efficiency and reduced expenses makes aftermarket components a compelling option for services looking for to enhance their upkeep and fixing budget plans.

Diverse Array of Options Available

Among the aftermarket components market for hefty equipment, a myriad of diverse choices stands ready to deal with the specific demands and demands of companies. This considerable series of aftermarket components offers businesses the adaptability to choose items that line up closely with their machinery specs and spending plan restrictions. From engine parts to hydraulic parts, filters, undercarriage elements, and extra, businesses can pick from various aftermarket choices customized to various equipment brand names and versions.

Additionally, the aftermarket components market provides services with the chance to check out options that may not be readily available through initial tools producers (OEMs) This variety in alternatives makes it possible for services to find cost-effective remedies without jeopardizing on high quality or efficiency - aftermarket construction parts. Whether a company focuses on toughness, cost competitiveness, or particular efficiency qualities, the aftermarket components market uses a vast option to satisfy these distinctive choices

Compatibility With Various Equipment Brands

By providing components that are developed to fit seamlessly with equipment from various brands, aftermarket suppliers make it possible for companies to streamline their upkeep processes and supply administration. This flexibility in compatibility also indicates that companies can combine their components sourcing efforts, lowering the time and sources spent on looking for particular elements for each and every device in their fleet.

Moreover, the capability to make use of aftermarket parts across various equipment brands can result in expense financial savings for businesses. As opposed to depending only on original devices visit the site supplier (OEM) components, which can be much more pricey, companies can take advantage of aftermarket options that offer similar top quality at a much more competitive cost factor. This economical technique to parts purchase contributes to total savings for hefty equipment drivers while making sure that devices continues to be operational and effective.

Quick Schedule and Easy Accessibility

With the raising need for effective maintenance services in the heavy equipment sector, timely accessibility and practical access to aftermarket parts have actually come to be extremely important for businesses looking for to maximize their procedures. Quick accessibility of aftermarket parts makes sure that equipment downtime is decreased, permitting firms to return to procedures quickly without long term interruptions. This not only boosts productivity but also protects against profits loss related to extended durations of lack of exercise.

Easy access to aftermarket components is equally essential as it simplifies the upkeep process (aftermarket construction parts). When components are easily available, upkeep groups can swiftly acquire the needed components without extensive preparations or delays. Refined access to aftermarket parts likewise enhances general operational effectiveness by lowering the moment and effort needed to resource and replace elements, ultimately adding to cost financial savings and improved tools uptime

Improved Value for Maintenance Budgets

Additionally, the decreased lead times associated with aftermarket a fantastic read components enable organizations to improve their upkeep processes. By maximizing maintenance budgets via the usage of aftermarket parts, organizations can accomplish a competitive side in their market while maintaining earnings and operational quality.

Final Thought

In conclusion, aftermarket parts for heavy machinery use an affordable solution for maintenance requirements. On the whole, using aftermarket parts can unlock significant cost-saving benefits for organizations in need of heavy machinery maintenance.

When it comes to heavy machinery maintenance, the choice between original devices maker (OEM) components and aftermarket components is a choice that holds relevance past the surface area.The remarkable top quality efficiency supplied by aftermarket components for hefty equipment comes at considerably lower costs compared to OEM parts. These parts undergo rigorous testing processes to ensure they meet industry criteria and requirements, offering a degree of integrity that is on the same level with OEM parts.

By choosing for aftermarket parts, companies can access top quality components at a portion of the price of OEM parts, enabling them to allocate their sources extra effectively and successfully. Aftermarket parts frequently come at a fraction of the price of OEM components, enabling companies to stretch their upkeep budget plans additionally and assign resources to various other essential locations.

Report this page